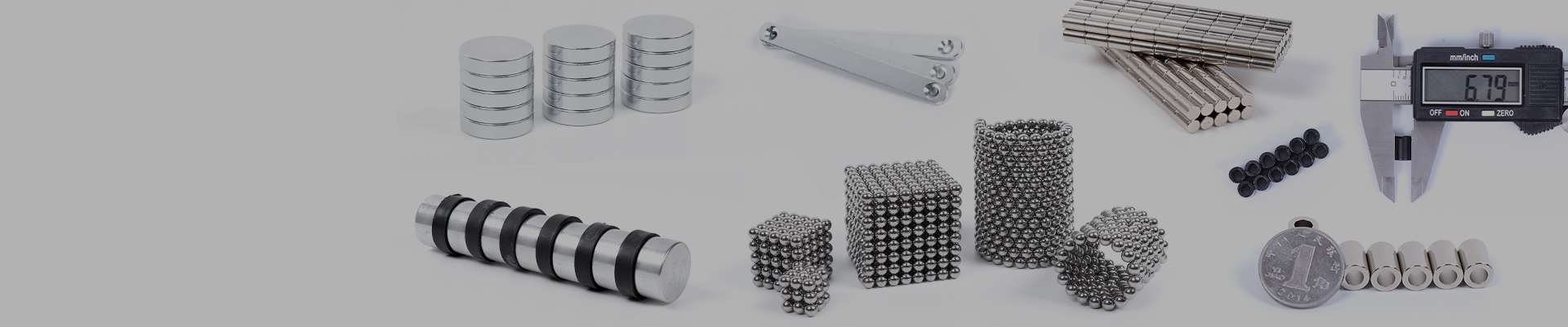

01 Small neodymium magnets, hides a huge energy, we consider the actual use of customers, so we will add disk between magnet, to facilitate the client access, and our colleagues are of experience, action quick and efficient, the daily shipments are very large. This is our control of the speed, efficiency and details.

02 This is our face grinding machine for square Alnico magnets. The workers on the left are installing the products, and on the right are checking the size of the magnets. All our products are subjected to such inspection in every process. Only qualified products will flow into the next step which ensure the quality control of production.

03 This is the electroplating process of magnets, placed the magnets which need to electroplate in the electroplating tank, according to the needs of customers on ZN, NI, NICUNI, Epoxy, Gold and other coatings. The electroplating solution cover the magnets in all aspects with the operation of the machine rotation. We have our own electroplating factory, so we can better control and ensure the quality and efficiency of magnets delivery.

04 Now is the new era of human-machine integration, robots will gradually lead the new trend of The Times and liberate human's hands, help human work more convenient and efficient. In order to ensure the quality of products, after the automated robotic inspection equipment test and then plus manual audit, to ensure the quality of products.

05

This is our Xinfeng automatic magnetization equipment, it also can automatically detect whether the magnets are qualified after magnetization, it will automatically eliminate the early warning unqualified products, to achieve 100% qualified products. Automation as the core technology in Xinfeng Magnet, commit to creating become the digital intelligent high-end equipment manufacturing enterprises in magnetic material industry, to win the market with scientific and technological innovation.

06

This is Hangzhou Xinfeng automatic magnetization, automatic feeding, automatic marking equipment. High-end scientific and technological equipment to make high-quality products escort, these are our Xinfeng magnet core competitiveness.

07

This is our Xinfeng automatic size appearance detection equipment, which can be used to automatically detect the appearance of magnets. If there have bumps, internal injuries and other appearance defects, as well as the size, out-of-tolerance and size misalignment products will be selected and classified by themselves to avoid defective products mixed in qualified products. It is precisely because of the support of these automation equipment, so that every magnet made by Xinfeng factory is a boutique.

08

This is Hangzhou Xinfeng Automatic Double Feed Magnetizing Machine of NdFeb magnets. According to the magnetization requirements of permanent magnet material, choose the main capacitor and SCR which were selected after 8 million durability tests. Magnetization fixture design and manufacturing can meet the radial, axial, radial, multipole, inclined pole and other different magnetization requirements, and according to the needs of intelligent quantitative magnetization, assembly magnetization, the whole machine of magnetization and other magnetization methods. By customization of magnetic field distribution measuring instrument, it is successfully realized in the on-line detection of magnetic field distribution and flux distribution of circular, ring magnets and all kinds of permanent magnet motor products. It is fast and accurate especially for the magnetic parts with small pole distance.

09 Xinfeng magnetic material in modern production model, especially in the standardized model, in order to reduce the labor intensity of workers, and make the production more standardized and meticulous, we introduce the assembly line operations, so that the worker can automatically realize some special working action of the products. In the production model of the same products with multiple stations, centralized operation of the needed products to simplify the disadvantages of workers' multi-station operation to improve the work efficiency, and to achieve single-point centralized control of product quality.

10 Xinfeng magnetic materials strict control in the quality of the products, keep improving on products. Not only the equipment tests each ring magnet, but also have a manual second review, to ensure that the quality of the product is completely controlled. In addition, the data we test will be automatically connected to the computer, will be automatically saved and will be automatically made the form, let the product data to be realistic, never ambiguous.

11 This is one of our Xinfeng packaging production lines, happy working atmosphere, let staffs work in a comfortable environment. And under the strict product selection system, accurate quality control of products, which is the epitome of our enterprise culture, not only respect and protect the rights of staffs, but also responsible for customers and product the high-quality products with a good price.

12 Our products in the machine for automatic detection, we still have to go through manual testing. All our products are in such high exposure environment with multi-angle inspection, to ensure that each magnet deliver in the market is a boutique. After double checking of machine and artificial, the magnets can't flow to the next link if there has any flaw. Only qualified products will enter into the next process.

13 This is our Automatic Wafer Testing Equipment for some wafer magnets. This equipment can accelerate the efficiency of production testing and greatly shorten the time, automatic detection, automatic magnetization, automatic add gasket, automatic mark. It can produce 1 million quantities of output value a day, and can ensure that the product qualification rate of 100%. Xinfeng has been winning the market and the trust of customers with scientific and technological innovation.

14 This is our Xinfeng Magnet special vibration disc automatic feeding equipment, it can realize the testing of magnets with length, height, diameter, mixing, deformation, lack of material, burrs, black spots, scratches and etc., the inspection accuracy is up to 1 mu, speed is up to 1200pcs per minute, we have more than 10 units such equipment and each in about 200000 yuan or so. Xinfeng has spared no effort to advance on the road of realizing technological innovation of enterprises.

15 This is our Xinfeng customized equipment which is of automatic detection, shimming, inkjet printing, marking and magnetization for square magnets. It can greatly improve the working efficiency that customized guide rails according to the specific product specifications. It can be automatically detected the number of 100,000 pieces magnets every day. This kind of automatic integrated magnet processing equipment, including the work table, the work table is provided with a feeding system, magnetizing system, magnetic flux detection system, classification system and inkjet system. The equipment can automatic inkjet print, automatic magnetization, automatic magnetic flux detection, automatic marking and classification for magnets with simple operation, low labor intensity, high production efficiency, test repeatability and accuracy and relatively safe.