OEM/ODM Manufacturer Flexible Neodymium Magnets - Neodymium Magnet Super Magnet Strong Magnet – Xinfeng Detail:

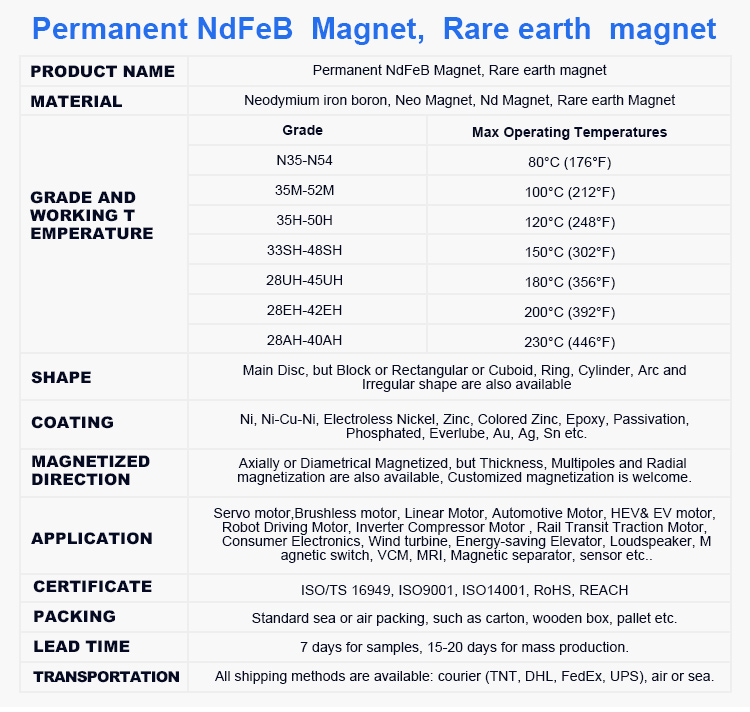

PRODUCT INTRODUCTION

NdFeb has the best performance among the rare-earth permanent magnets. It is the rare earth permanent magnet with the strongest magnetic property at present. It has an extreme high BH max and good Hcj, and greatly machinability. It is the most widely used permanent magnet material in the industrial field and known as the “Magnet King”.

As NdFeB is easily oxidized or corroded, it can be plated or coated according to the requirements of the working environment of the product. The coating could be nickel, nickel-copper-nickel, zinc, tin, chromium, black epoxy, phosphorization, not plating, etc. All coatings meet the requirements of RoHS.

NdFeb is the alloy magnet of Neodymium (Nd), Iron (Fe), Boron (B) and some other microelements, produce through the Powder Metallurgy technology. China owns abundant rare earth resources and supplies the world 70% rare earth magnets.

At present, the performance of our products has reached the first-class level of the world. Our products have been widely used in aerospace, medical, electronic equipment, automotive equipment, motors, generators, nuclear magnetic resonance, magnetic levitation, magnetic separator, electro-acoustic fields, etc.

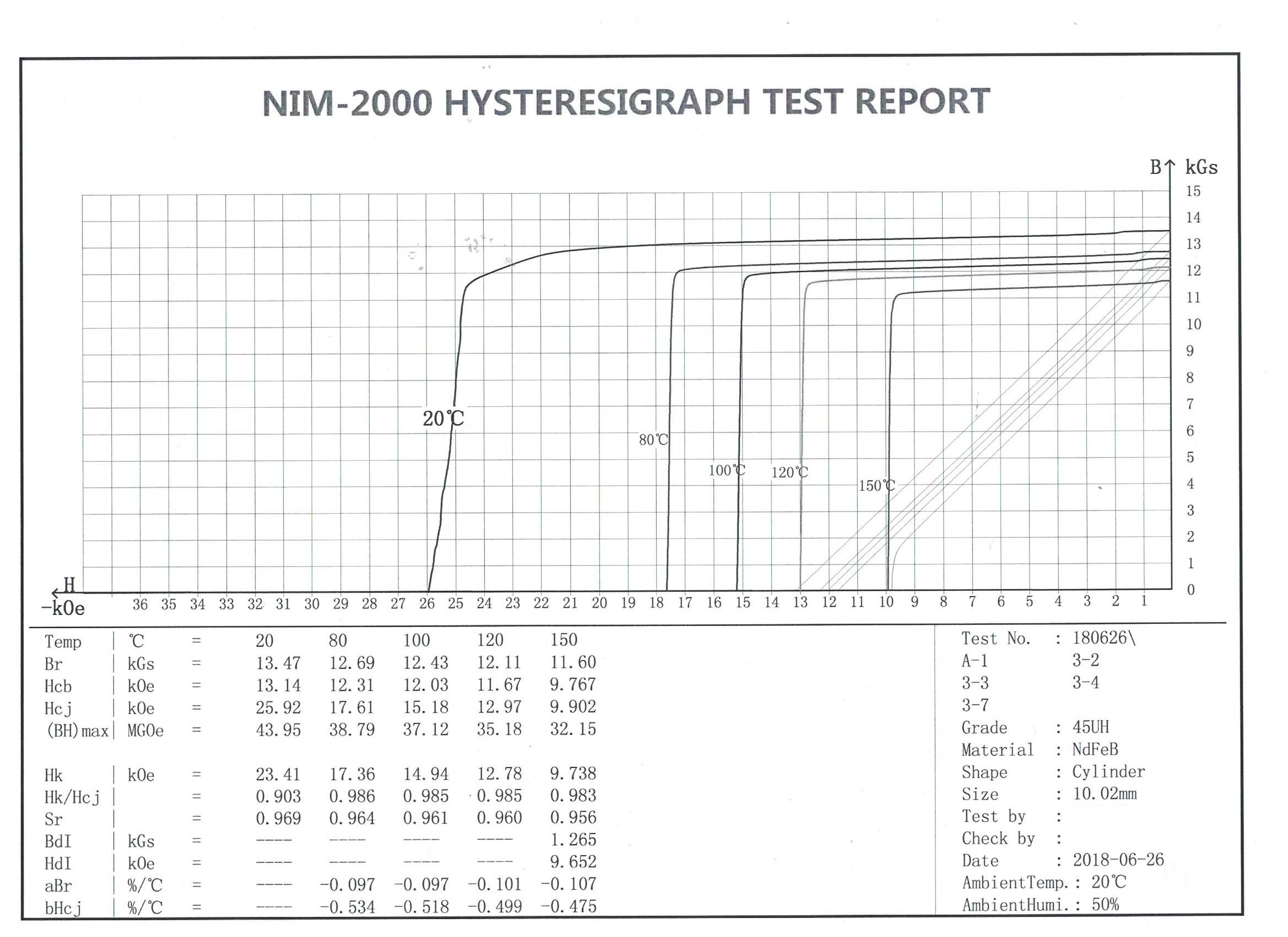

PRODUCT DETAILS AND CURVE

Product Details

Curve

MAGNETIC PROPERTY PARAMETERS OF SINTERED NDFEB MAGNET

|

Grade |

Br |

Hcb |

Hcj |

( BH )max |

Tw:℃ |

|

mT(kGs) |

kA/m(kOe) |

kA/m(kOe) |

kJ/m3(MGOe) |

||

|

N35 |

1170-1220(11.7-12.2) |

≥ 868(10.9) |

≥ 955(12) |

263-287(33-36) |

80 ℃ |

|

N38 |

1220-1250(12.2-12.5) |

≥ 899(11.3) |

≥ 955(12) |

287-310(36-39) |

80 ℃ |

|

N40 |

1250-1280(12.5-12.8) |

≥ 907(11.4) |

≥ 955(12) |

302-326(38-41) |

80 ℃ |

|

N42 |

1280-1320(12.8-13.2) |

≥ 915(11.5) |

≥ 955(12) |

318-342(41-43) |

80 ℃ |

|

N45 |

1320-1380(13.2-13.8) |

≥ 923(11.6) |

≥ 955(12) |

342-366(43-46) |

80 ℃ |

|

N48 |

1380-1420(13.8-14.2) |

≥ 923(11.6) |

≥ 955(12) |

366-390(46-49) |

80 ℃ |

|

N50 |

1400-1450(14.0-14.5) |

≥ 796(10.0) |

≥ 876(11) |

374-406(47-51) |

80 ℃ |

|

N52 |

1430-1480(14.3-14.8) |

≥ 796(10.0) |

≥ 876(11) |

390-422(49-53) |

80 ℃ |

|

N54 |

1450-1510(14.5-15.1) |

≥ 836(10.5) |

≥ 876(11) |

406-438(51-55) |

80 ℃ |

|

33M |

1130-1170(11.3-11.7) |

≥ 836(10.5) |

≥1114(14) |

247-263(31-33) |

100 ℃ |

|

35M |

1170-1220(11.7-12.2) |

≥ 868(10.9) |

≥1114(14) |

263-287(33-36) |

100 ℃ |

|

38M |

1220-1250(12.2-12.5) |

≥ 899(11.3) |

≥1114(14) |

287-310(36-39) |

100 ℃ |

|

40M |

1250-1280(12.5-12.8) |

≥ 923(11.6) |

≥1114(14) |

302-326(38-41) |

100 ℃ |

|

42M |

1280-1320(12.8-13.2) |

≥ 955(12.0) |

≥1114(14) |

318-342(40-43) |

100 ℃ |

|

45M |

1320-1380(13.2-13.8) |

≥ 995(12.5) |

≥1114(14) |

342-366(43-46) |

100 ℃ |

|

48M |

1360-1430(13.6-14.3) |

≥ 1027(12.9) |

≥1114(14) |

366-390(46-49) |

100 ℃ |

|

50M |

1400-1450(14.0-14.5) |

≥ 1033(13.0) |

≥1114(14) |

382-406(48-51) |

100 ℃ |

|

52M |

1420-1480(14.2-14.8) |

≥ 1059(13.3) |

≥1114(14) |

390-422(49-53) |

100 ℃ |

|

35H |

1170-1220(11.7-12.2) |

≥ 868(10.9) |

≥1353(17) |

263-287(33-36) |

120 ℃ |

|

38H |

1220-1250(12.2-12.5) |

≥ 899(11.3) |

≥1353(17) |

287-310(36-39) |

120 ℃ |

|

40H |

1250-1280(12.5-12.8) |

≥ 923(11.6) |

≥1353(17) |

302-326(38-41) |

120 ℃ |

|

42H |

1280-1320(12.8-13.2) |

≥ 955(12.0) |

≥1353(17) |

318-342(40-43) |

120 ℃ |

|

45H |

1320-1360(13.2-13.6) |

≥ 963(12.1) |

≥1353(17) |

326-358(43-46) |

120 ℃ |

|

48H |

1370-1430(13.7-14.3) |

≥ 995(12.5) |

≥1353(17) |

366-390(46-49) |

120 ℃ |

|

50H |

1400-1450(14.0-14.5) |

≥ 1027(12.9) |

≥1274(16) |

374-406(47-51) |

120 ℃ |

|

35SH |

1170-1220(11.7-12.2) |

≥ 876(11.0) |

≥1592(20) |

263-287(33-36) |

150 ℃ |

|

38SH |

1220-1250(12.2-12.5) |

≥ 907(11.4) |

≥1592(20) |

287-310(36-39) |

150 ℃ |

|

40SH |

1250-1280(12.5-12.8) |

≥ 939(11.8) |

≥1592(20) |

302-326(38-41) |

150 ℃ |

|

42SH |

1280-1320(12.8-13.2) |

≥ 987(12.4) |

≥1592(20) |

318-342(40-43) |

150 ℃ |

|

45SH |

1320-1380(13.2-13.8) |

≥ 1003(12.6) |

≥1592(20) |

342-366(43-46) |

150 ℃ |

|

48SH |

1360-1400(13.6-14.0) |

≥ 1034(13) |

≥1592(20) |

366-390(46-49) |

150 ℃ |

|

28UH |

1020-1080(10.2-10.8) |

≥ 764(9.6) |

≥1990(25) |

207-231(26-29) |

180 ℃ |

|

30UH |

1080-1130(10.8-11.3) |

≥ 812(10.2) |

≥1990(25) |

223-247(28-31) |

180 ℃ |

|

33UH |

1130-1170(11.3-11.7) |

≥ 852(10.7) |

≥1990(25) |

247-271(31-34) |

180 ℃ |

|

35UH |

1180-1220(11.8-12.2) |

≥ 860(10.8) |

≥1990(25) |

263-287(33-36) |

180 ℃ |

|

38UH |

1220-1250(12.2-12.5) |

≥ 876(11.0) |

≥1990(25) |

287-310(36-39) |

180 ℃ |

|

40UH |

1250-1280(12.5-12.8) |

≥ 899(11.3) |

≥1990(25) |

302-326(38-41) |

180 ℃ |

|

42UH |

1290-1350(12.9-13.5) |

≥ 963(12.1) |

≥1990(25) |

318-350(40-44) |

180 ℃ |

|

28EH |

1040-1090(10.4-10.9) |

≥ 780(9.8) |

≥2388(30) |

207-231(26-29) |

200 ℃ |

|

30EH |

1080-1130(10.8-11.3) |

≥ 812(10.2) |

≥2388(30) |

223-247(28-31) |

200 ℃ |

|

33EH |

1130-1170(11.3-11.7) |

≥ 876(10.5) |

≥2388(30) |

247-271(31-34) |

200 ℃ |

|

35EH |

1170-1220(11.7-12.2) |

≥ 876(11.0) |

≥2388(30) |

263-287(33-36) |

200 ℃ |

|

38EH |

1220-1250(12.2-12.5) |

≥ 899(11.3) |

≥2388(30) |

287-310(36-39) |

200 ℃ |

|

40EH |

1260-1290(12.6-12.9) |

≥ 939(11.6) |

≥2388(30) |

302-326(38-41) |

200 ℃ |

|

28AH |

1040-1090(10.4-10.9) |

≥ 787(9.9) |

≥2624(33) |

207-231(26-29) |

230 ℃ |

|

30AH |

1080-1140(10.8-11.3) |

≥ 819(10.3) |

≥2624(33) |

223-247(28-31) |

230 ℃ |

|

33AH |

1130-1170(11.3-11.7) |

≥ 843(10.6) |

≥2624(33) |

247-271(31-34) |

230 ℃ |

|

35AH |

1170-1220(11.7-12.2) |

≥ 876(11) |

≥2624(33) |

263-287(33-36) |

230 ℃ |

|

Note: 1. The above magnetic parameters and physical characteristics are data at room temperature. |

|||||

|

2.The maximum operating temperature depends on the magnetic aspect ratio, coating and environment factors. |

|||||

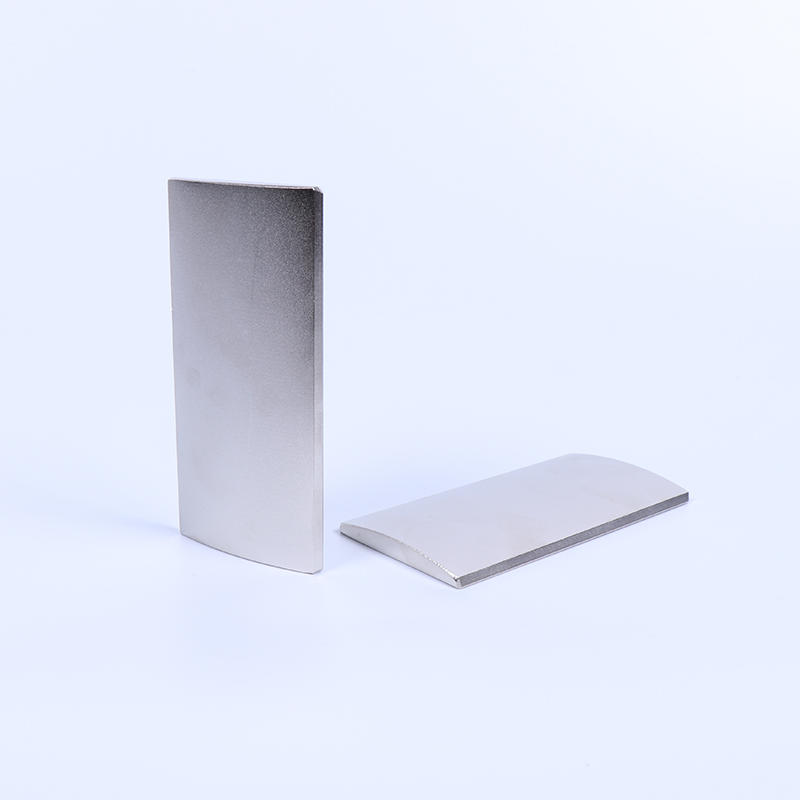

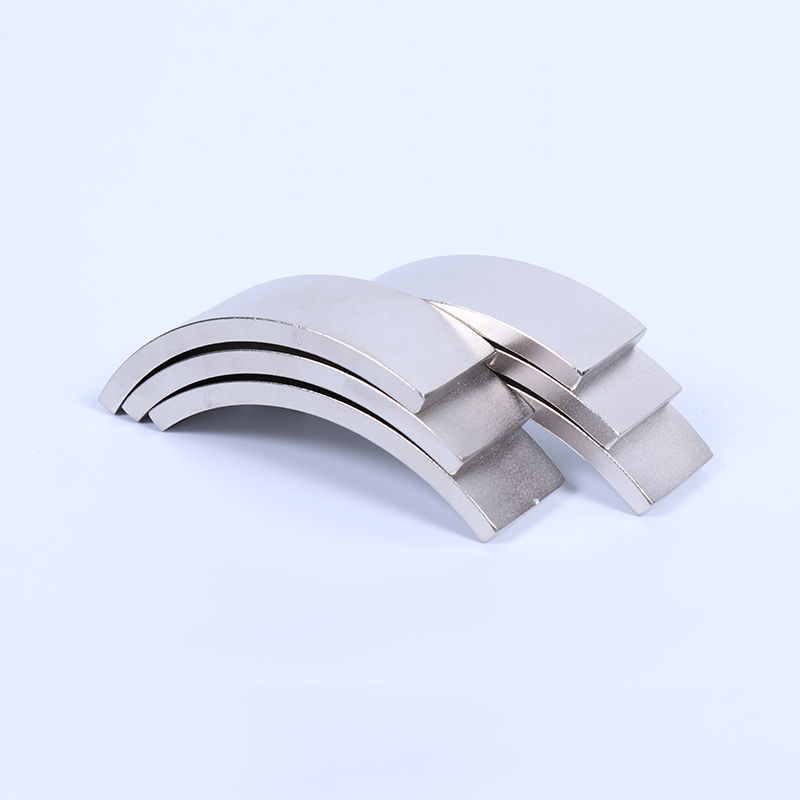

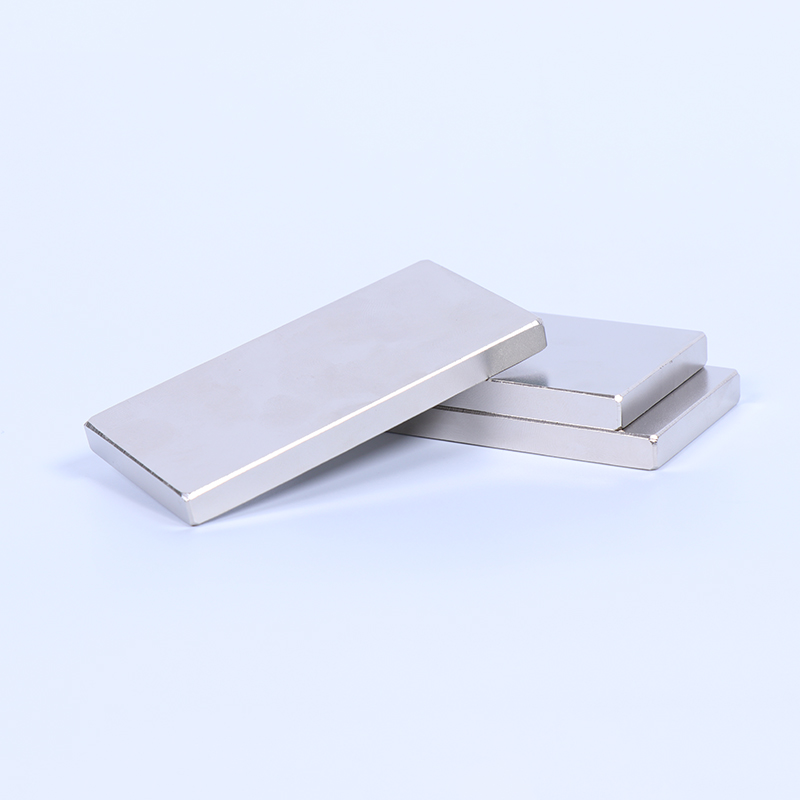

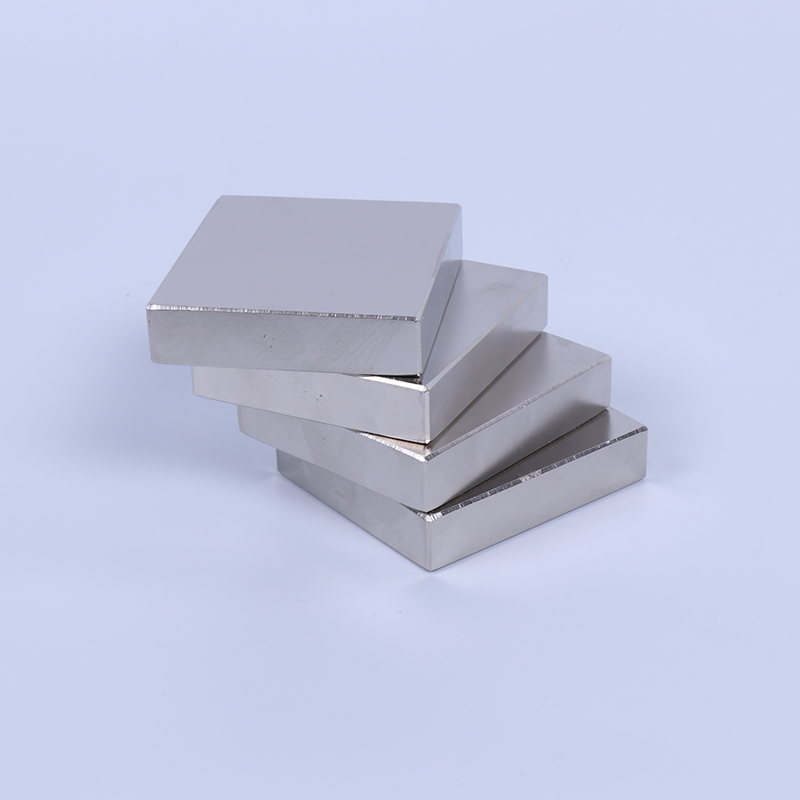

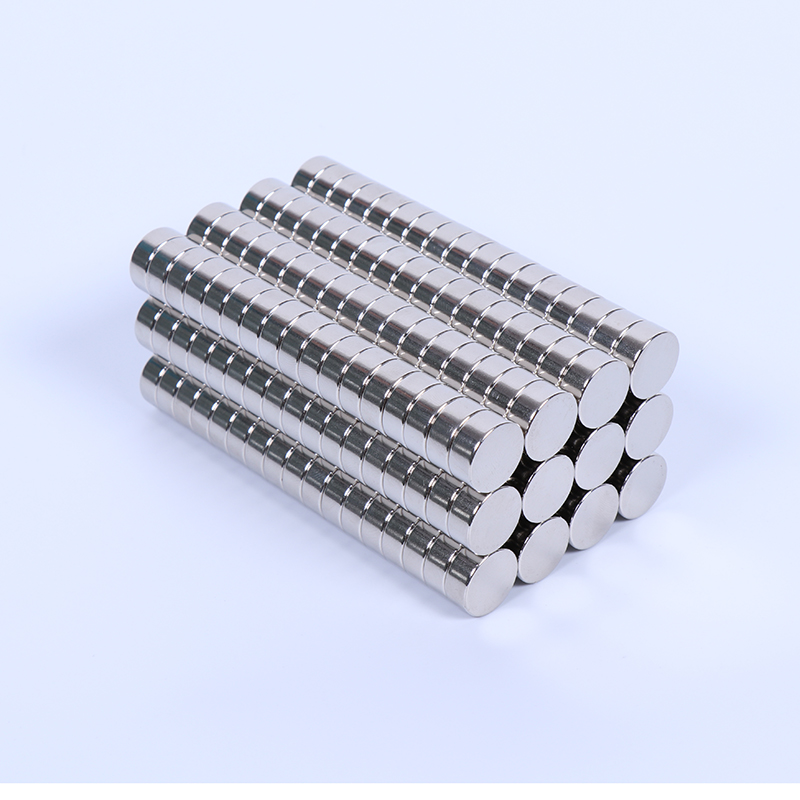

PRODUCT DISPLAY

Product detail pictures:

Related Product Guide:

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for OEM/ODM Manufacturer Flexible Neodymium Magnets - Neodymium Magnet Super Magnet Strong Magnet – Xinfeng , The product will supply to all over the world, such as: Malta, Florida, luzern, There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

We have been looking for a professional and responsible supplier, and now we find it.