Factory Cheap Magnetic Alnico - Alnico Permanent Manget Rare Earth Magnet – Xinfeng Detail:

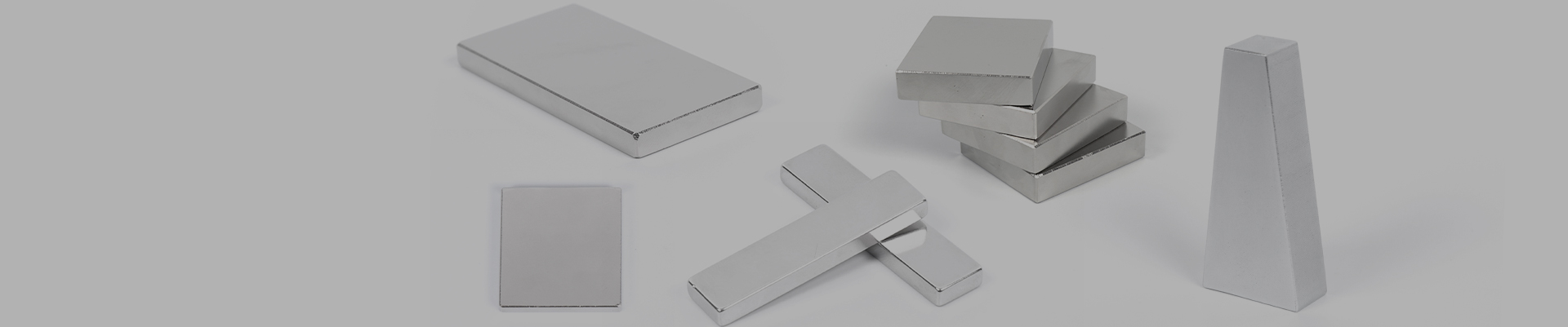

PRODUCT INTRODUCTION

Alnico Magnet is the alloy magnet of Aluminum, Nickel, Cobalt, Iron and other trace metal elements, which is the first generation of permanent magnet materials that developed at the earliest.

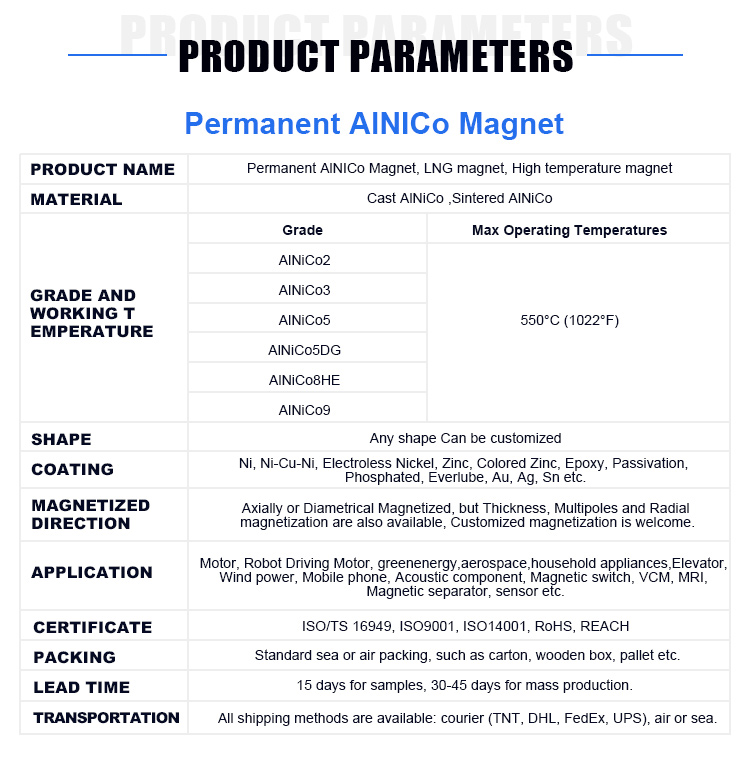

Alnico Permanent Magnet materials have the advantage of high Br (up to 1.5T) and low temperature coefficient, stable magnetic, high temperature resistance, moisture resistance and oxidation resistance. When the temperature coefficient is -0.02%/℃, the maximum operating temperature can reach 550℃. The disadvantage is that the coercivity is very low and the demagnetization curve is nonlinear. Therefore, although Alnico magnets are easily magnetized, they are also easy to demagnetize.

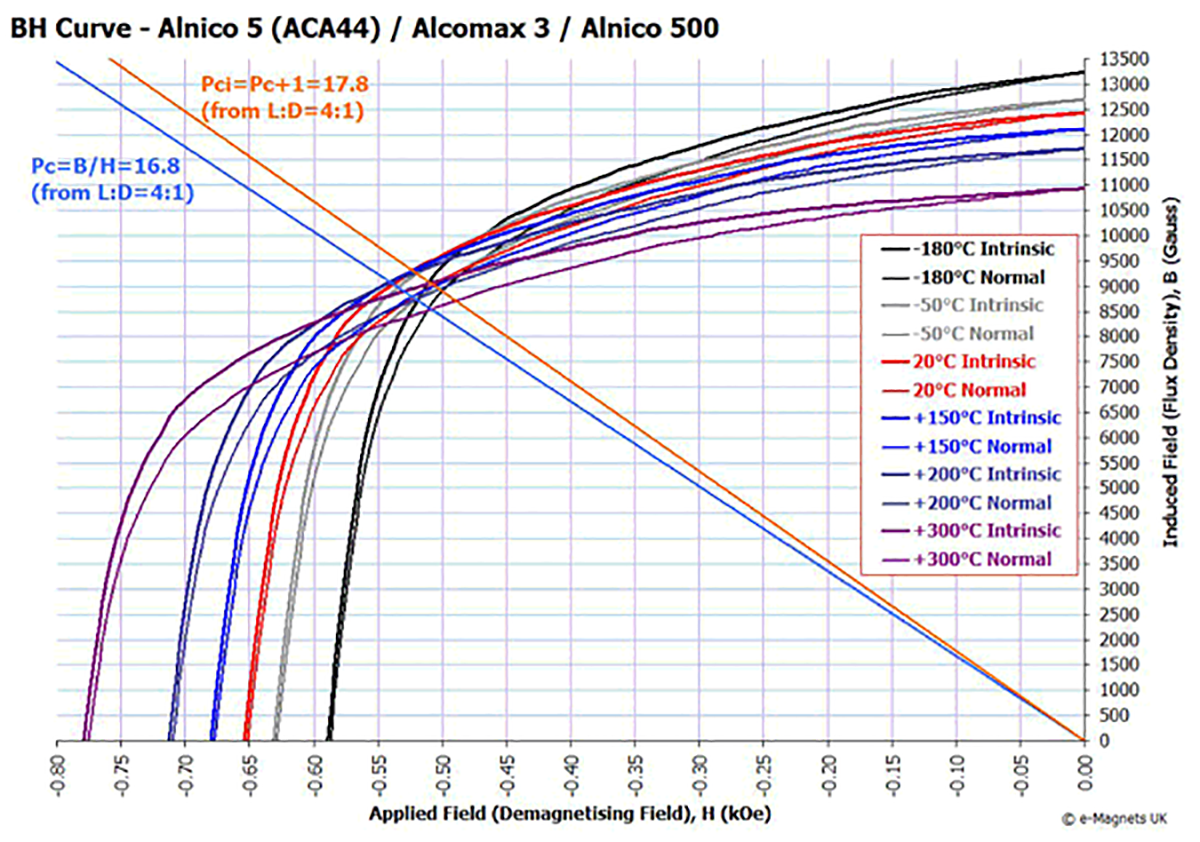

According to the production process, it can be divided into Sintered Alnico and Cast Alnico. The shape of the product is mostly round and square. Casting process can be processed into different sizes and shapes;

Compared with the casting process, the sintered product is limited to small size products. The dimensional tolerance of sintered blanks is better than that of the cast product while the magnetic properties are slightly lower than that of the cast product

Alnico is now widely used in magnetoelectric instruments, electromagnetic flowmeters, relays, teaching instruments, electric guitar pickups, microphones, sensors, traveling wave tubes, cow magnets and other fields.

PRODUCT DETAILS AND CURVE

Product Details

Curve

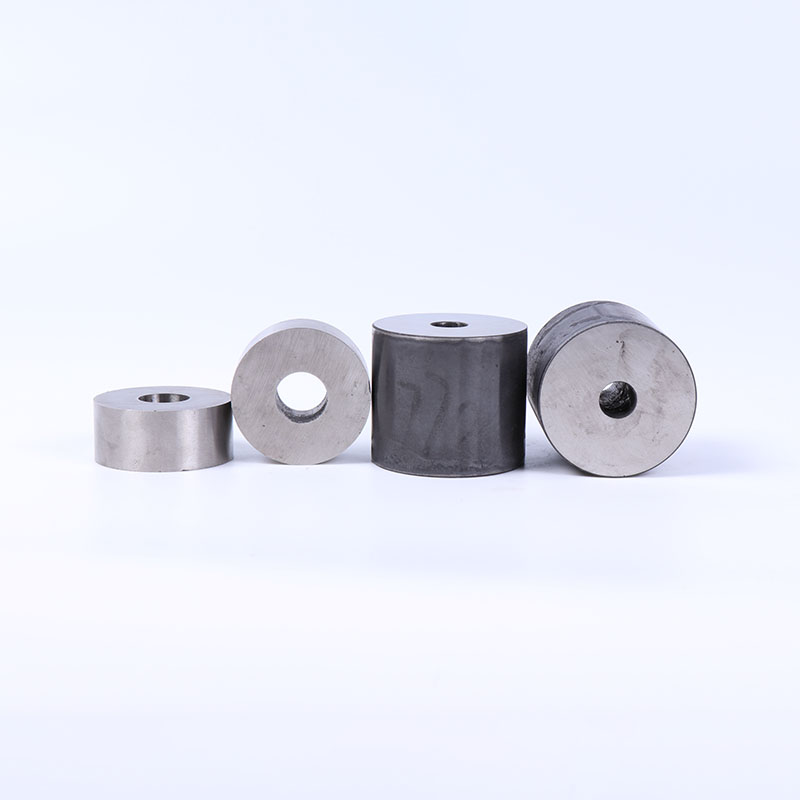

MAGNETIC PROPERTY PARAMETERS OF CAST ALNICO

|

Grade |

US Standard |

Br |

Hcb |

(BH)max |

Tc |

Tw |

T.C.α(Br) |

T.C.α(Hcj) |

|

mT/Gs |

kA/m /Oe |

kJ/m3/MGOe |

℃ |

℃ |

%/℃ |

%/℃ |

||

|

Typical Value |

Typical Value |

Typical Value |

Typical Value |

Typical Value |

Typical Value |

Typical Value |

||

|

LN10 |

ALNICO3 |

600/6000 |

40/500 |

10/1.25 |

750 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNG10 |

600/6000 |

44/550 |

10/1.25 |

750 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNG12 |

ALNICO2 |

700/7000 |

44/550 |

12/1.50 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNG13 |

680/6800 |

48/600 |

13/1.63 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNG16 |

ALNICO4 |

800/8000 |

48/600 |

16/2.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNG18 |

900/9000 |

48/600 |

18/2.25 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNG37 |

ALNICO5 |

1200/12000 |

48/600 |

37/4.63 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNG40 |

1230/12300 |

48/600 |

40/5.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNG44 |

1250/12500 |

52/650 |

44/5.50 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNG48 |

ALNICO5DG |

1280/12800 |

56/700 |

48/6.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNG52 |

1300/13000 |

56/700 |

52/6.50 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNG56 |

ALNICO5-7 |

1300/13000 |

58/720 |

56/7.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNG60 |

1330/13300 |

60/750 |

60/7.50 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT28 |

ALNICO6 |

1000/10000 |

56/700 |

28/3.50 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNGT30 |

1100/11000 |

56/700 |

30/3.75 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT18 |

ALNICO8 |

580/5800 |

80/1000 |

18/2.25 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNGT32 |

800/8000 |

100/1250 |

32/4.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT38 |

800/8000 |

110/1380 |

38/4.75 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT44 |

850/8500 |

115/1450 |

44/5.50 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT48 |

ALNICO8HE |

900/9000 |

120/1500 |

48/6.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNGT60 |

ALNICO9 |

900/9000 |

110/1380 |

60/7.50 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNGT72 |

1050/10500 |

112/1400 |

72/9.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT80 |

1080/10800 |

120/1500 |

80/10.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT88 |

1100/11000 |

115/1450 |

88/11.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT96 |

1150/11500 |

118/1480 |

96/12.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT36J |

ALNICO8HC |

700/7000 |

140/1750 |

36/4.50 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

LNGT48J |

800/8000 |

145/1820 |

48/6.00 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

LNGT52J |

850/8500 |

140/1750 |

52/6.50 |

800~850 |

550 |

-0.02 |

-0.03~-0.07 |

|

|

Note: Curie temperature and temperature coefficient are only used as reference, not as judgment criteria. Customers have special requirements, can be customized according to customer requirements. |

||||||||

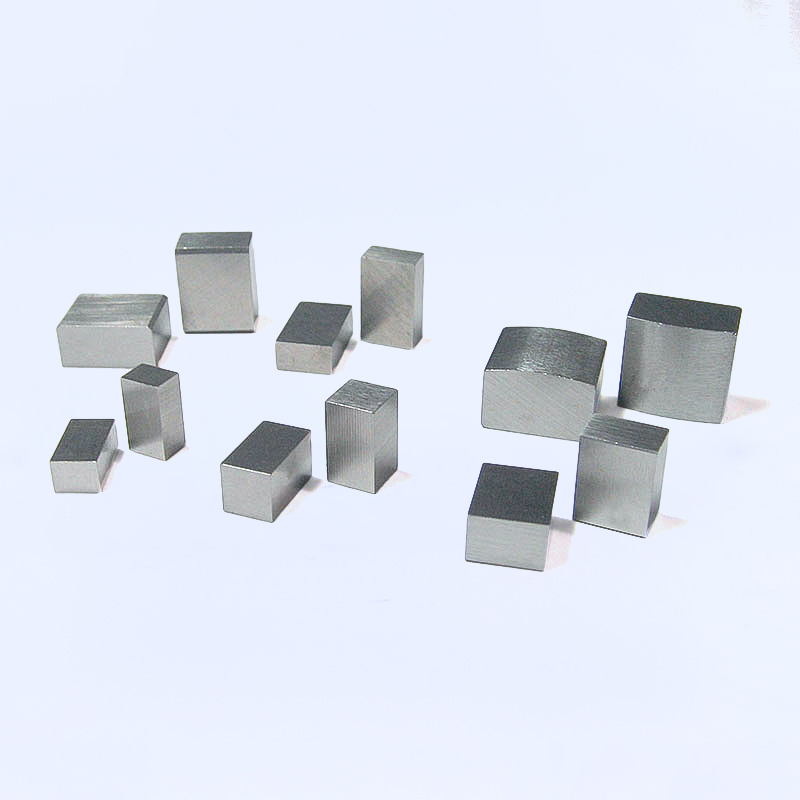

PRODUCT DISPLAY

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand abroad business" is our enhancement strategy for Factory Cheap Magnetic Alnico - Alnico Permanent Manget Rare Earth Magnet – Xinfeng , The product will supply to all over the world, such as: Hongkong, California, Jersey, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to provide professional, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We will serve you with all sincerity!

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.